Electrical

Unique Properties Meet Rigorous Demands

Electrical Composite Materials

The electrical industry relies on the properties of electrical composite materials for top performance. Unlike parts molded from plastic which can carbonize or melt during exposure to electrical arcing or tracking, thermoset composite materials experience minimal impact from these common electrical equipment conditions. AltraSet provides thermoset composite materials for this demanding industry in a variety of applications. Composites were more traditionally designed for structural materials. As compared to composites in structural materials, electronic composites emphasize processing into smaller parts which leads to lower costs for electrical composite materials. The use of thermoset components in electrical equipment took hold in the mid-1990s when the cost-effective, better-performing composites replaced traditional materials like engineered thermoplastics.Applications in the Electrical Industry

The unique properties of thermoset composites make the materials ideally suited to the rigors of use in the electrical industry. Phenolic-matrix and melamine composites are used in many electronics including printed circuit boards, gears, and insulators. Insulation, circuit boards and components requiring a high resistance to heat will often be made from a silicone-based composite. Additional applications include:- Control system components

- Circuit breakers

- Arc chutes

- Arc shields

- Terminal blocks and boards

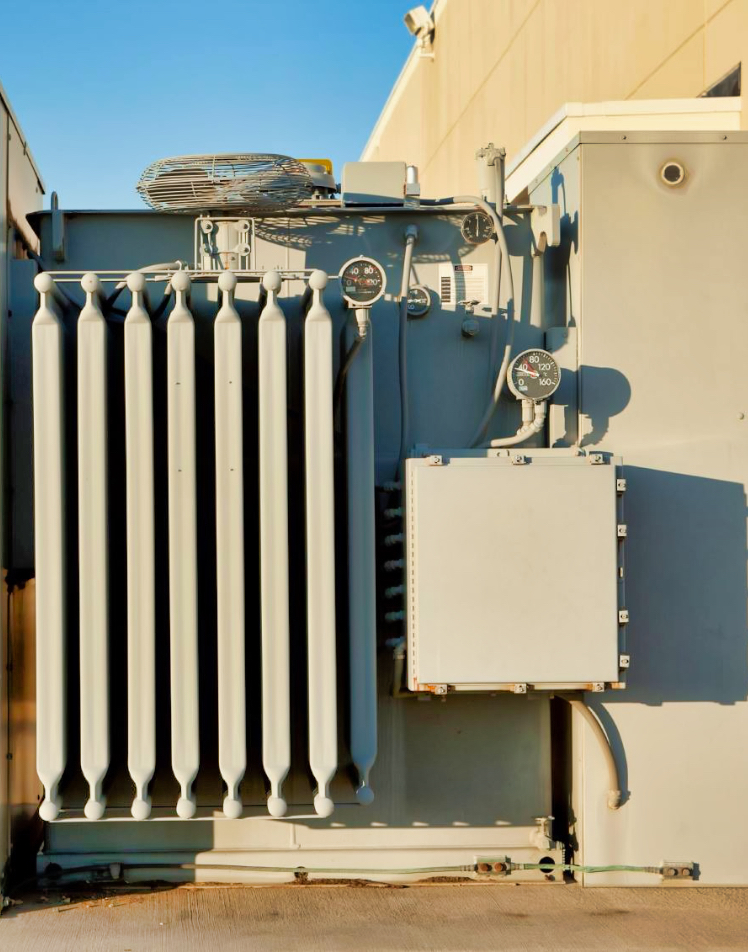

- Substation equipment

- Microwave antennas

- Standoff insulators

- Pole line hardware

- Printed wiring boards

- Switchgear

- Panelboards

- Server rooms

- Metering devices

- Lighting components

Strength and Heat Resistance

The risk of breakage, underperformance or failure in electrical equipment can have devastating safety consequences and significantly impact a company’s profits and performance. Electrical equipment requires components that withstand heat and friction and perform reliably over time. These properties are derived from the nature of the composite’s components. The resin matrix and the reinforcement comprise the major components. The dielectric strength of thermoset component materials has made thermoset composites the go-to material for electrical components. The unique property is the result of a network of cross-linked molecules that create a rigid structure. Chemical bonds hold the molecules in place. As a result, compounds made with thermoset binders keep their physical and electrical properties under mechanical loads during prolonged exposure to elevated temperatures. Thermoset composites have dielectric strength in excess of 15 kV/mm. In addition to being dielectric, AltraSet’s composite materials carry other properties that are well-suited for electrical use. These include:- High thermal conductivity

- Low thermal expansion

- Superior electrical insulation

- High/low electrical conductivity

- Electromagnetic interference (EMI) shielding effectiveness

- Heat resistance

- Track resistance

- Low coefficient of thermal expansion

- Comparative Tracking Index (CTI) values exceeding 600 volts

- Durability to withstand repeated use without a decrease in performance

- Moisture resistance for safety and durability

- Sound baffling for quieter operation

Evolving Demand

The growth of the electrical industry has provided an evolving market for electrical composite materials. As equipment gets more sophisticated and technology advances, the role of thermoset composites will continue to expand across industries and applications. The streamlining of composite manufacturing processes and the development of new manufacturing forms meet the demand for faster cycle times, make composites more cost effective and provide enhanced quality and lower processing costs. AltraSet’s engineers continually innovate to develop thermoset composite components that meet the safety and performance demands of each unique application within the electrical industry.Customized to Meet Your Needs

The demand for high-performance equipment in the electrical industry requires customized composite solutions that address constant use, heat, friction, temperature fluctuations, electrical properties and ongoing safety requirements. When you work with AltraSet, you get thermoset composites designed and engineered from cost-effective materials, which are produced to fit the rigors of electrical applications. AltraSet thermoset composites are custom produced for each job’s specific application. As the electrical industry evolves, AltraSet engineers will be ready to meet the new, more sophisticated demands.Thermoset composites have strong dielectric properties including arc and track resistance.

Our material engineering team can customize a material to fit your application and meet your exact specifications.